Equipment Management department, Sinopec Yizheng Chemical Fiber Co., Ltd. 211900

Ndemanga: Pepalali likuwunika zomwe zimayambitsa mayunitsi akuluakulu a turbo expander, imayika patsogolo njira zingapo zothetsera mavuto, ndikumvetsetsa zowopsa ndi njira zodzitetezera.Kupyolera mukugwiritsa ntchito ukadaulo wochotsa varnish, zowopsa zobisika zimachotsedwa ndipo chitetezo chamkati chagawo chimatsimikiziridwa.

1. mwachidule

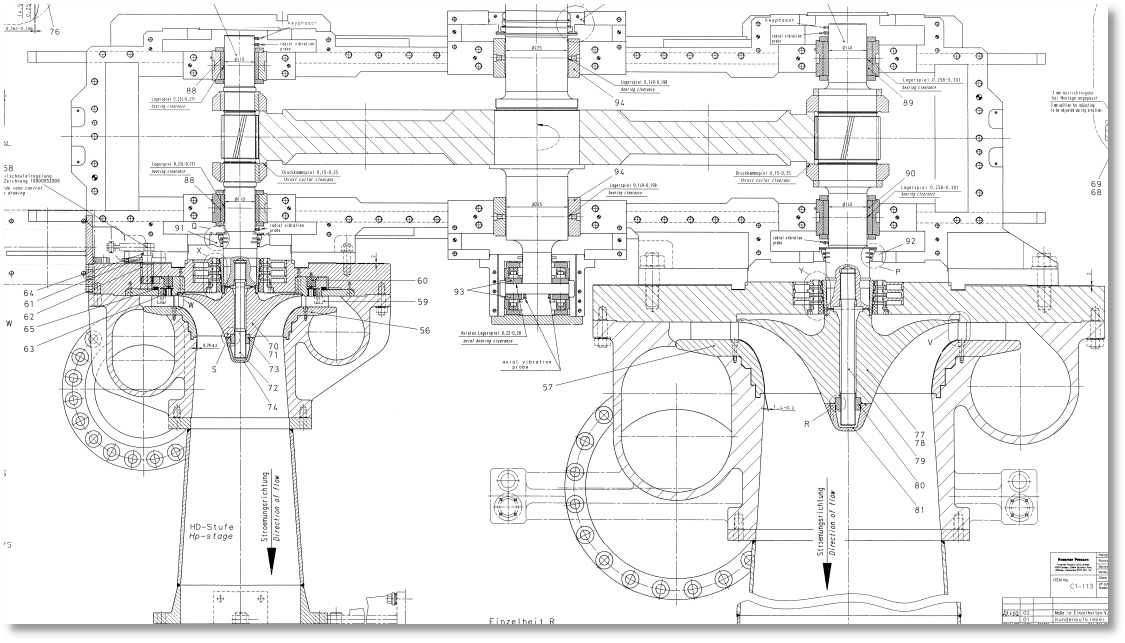

Chigawo cha air compressor cha 60 t/a PTA chomera cha Yizheng Chemical Fiber Co., Ltd. chili ndi zida zochokera ku Germany MAN Turbo.Chigawochi ndi chamagulu atatu-in-chimodzi, momwe mpweya wa compressor unit ndi multi-shaft-five-stage turbine unit, turbine condensing nthunzi imagwiritsidwa ntchito ngati makina oyendetsa makina a air compressor unit, ndi turbo expander. amagwiritsidwa ntchito ngati unit air compressor.Makina othandizira othandizira.Turbo expander imatengera kukulitsa kwa magawo awiri, iliyonse ili ndi doko loyamwa komanso doko lotulutsa mpweya, ndipo choyikapo chimatenga njira zitatu (onani Chithunzi 1)

Chithunzi 1 Mawonedwe a gawo la gawo lokulitsa (kumanzere: mbali yothamanga kwambiri; kumanja: mbali yotsika)

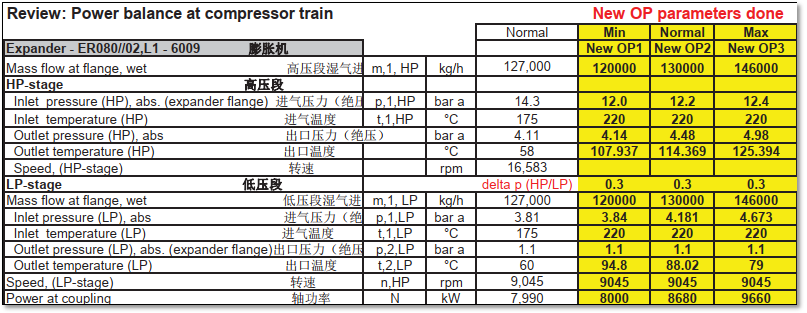

Zochita zazikulu za turbo expander ndi izi:

Kuthamanga kwapamwamba kwambiri ndi 16583 r / min, ndipo kutsika kwapakati-kuthamanga ndi 9045 r / min;oveteredwa mphamvu zonse za expander ndi 7990 KW, ndi otaya mlingo ndi 12700-150450-kg/h;Kuthamanga kolowera ndi 1.3Mpa, ndipo kuthamanga kwa mpweya ndi 0.003Mpa.Kutentha kwapadera kwa mbali yothamanga kwambiri ndi 175 ° C, ndipo kutentha kwa mpweya ndi 80 ° C;kutentha kwa kulowetsedwa kwa mbali yotsika kwambiri ndi 175 ° C, ndipo kutentha kwa mpweya ndi 45 ° C;seti ya ma tilting pads amagwiritsidwa ntchito kumapeto onse a kuthamanga kwambiri komanso kutsika kwapambali kwa giya zonyamula, iliyonse yokhala ndi mapadi 5, payipi yolowera mafuta imatha kulowa mafuta m'njira ziwiri, ndipo chilichonse chimakhala ndi bowo limodzi lolowera mafuta, Magulu 3 a 15 jekeseni nozzles mafuta, m'mimba mwake wa mphuno yolowera mafuta ndi 1.8mm, Pali mabowo 9 obwezeretsa mafuta, ndipo nthawi zonse, madoko 5 ndi midadada 4 amagwiritsidwa ntchito.Chigawo chachitatu-chimodzi ichi chimagwiritsa ntchito njira yokakamiza yopangira mafuta apakati kuchokera pamalo opaka mafuta.

2. Mavuto ndi ogwira ntchito

Mu 2018, kuti akwaniritse zofunikira za mpweya wa VOC, chipangizo chatsopano cha VOC chinawonjezeredwa ku chipangizo chothandizira mpweya wa mchira wa oxidation reactor, ndipo mpweya wa mchira udayikidwabe mu chowonjezera.Chifukwa mchere wa bromide mu mpweya woyambirira wa mchira umakhala ndi okosijeni pa kutentha kwakukulu, pali ma ion a bromide.Pofuna kupewa ma ion a bromidi kuti asasunthike ndikulekanitsa pamene mpweya wa mchira ukukula ndikugwira ntchito mu expander, zingayambitse dzimbiri pazitsulo zowonjezera ndi zipangizo zotsatila.Chifukwa chake, ndikofunikira kuwonjezera gawo lokulitsa.Kutentha kwa m'kamwa ndi kutentha kwa mpweya wa mbali yothamanga kwambiri ndi mbali yotsika (onani Table 1).

Gulu 1 Mndandanda wa kutentha kwa ntchito polowera ndi kutulutsa kwa chowonjezera chisanachitike komanso pambuyo pa kusintha kwa VOC

| AYI. | Kusintha kwa parameter | Kusintha kwa zakale | Pambuyo kusintha |

| 1 | Kuthamanga kwambiri kwa mbali ya mpweya kutentha | 175 ° C | 190 ° C |

| 2 | High kuthamanga mbali utsi kutentha kutentha | 80 ℃ | 85 °C |

| 3 | Kutsika kwapang'onopang'ono mbali ya mpweya kutentha | 175 ° C | 195 ° C |

| 4 | Low kuthamanga mbali utsi kutentha kutentha | 45 °C | 65 °C |

Pambuyo pa kusinthika kwa VOC, kutentha kwa mbali yopanda mphamvu yonyamula kumapeto kwapansi kwakhala kokhazikika pafupifupi 80 ° C (kutentha kwa alamu kwa kunyamula apa ndi 110 ° C, ndipo kutentha kwakukulu ndi 120 ° C).Kusintha kwa VOC kutayambika pa Januware 6, 2019, kutentha kwa mbali yopanda mphamvu yonyamula kumapeto kwa chowonjezera chowonjezera kunakwera pang'onopang'ono, ndipo kutentha kwapamwamba kwambiri kunali pafupi ndi kutentha kwakukulu komwe kunanenedwa kwa 120 ° C, koma magawo ogwedezeka sanasinthe kwambiri panthawiyi (onani Chithunzi 2).

Chithunzi cha 2 Chithunzi cha kuchuluka kwa kutuluka kwa chowonjezera komanso kugwedezeka kwa shaft side-drive ndi kutentha

1 - mzere wothamanga 2 - mzere wosayendetsa galimoto 3 - mzere wosayendetsa shaft vibration

3. Kusanthula chifukwa ndi njira ya chithandizo

Pambuyo poyang'ana ndi kusanthula kutentha kwa mayendedwe a turbine mayendedwe a nthunzi, ndikuchotsa zovuta zowonetsera chida pamalopo, kusinthasintha kwa ndondomeko, kufalikira kwa mavalidwe a nthunzi ya turbine brush, kusinthasintha kwa zida, ndi khalidwe la magawo, zifukwa zazikulu zomwe zimachititsa kusinthasintha kwa kutentha. ndi:

3.1 Zifukwa za kukwera kwa kutentha kwa mbali yopanda mphamvu yonyamula pamapeto otsika a chowonjezera

3.1.1 Kuyang'ana kwa disassembly kunapeza kuti mtunda pakati pa chonyamulira ndi tsinde ndi ma meshing chilolezo cha mano a zida zinali zachilendo.Kupatula ma varnish omwe amaganiziridwa kuti ali kumbali yosakhala ndi impeller yonyamula pamwamba pamtunda wocheperako wa chowonjezera (onani Chithunzi 3), palibe zolakwika zomwe zidapezeka mumayendedwe ena.

Chithunzi 3 Chithunzi chakuthupi cha chonyamula chosayendetsa ndi kinematic pair of expander

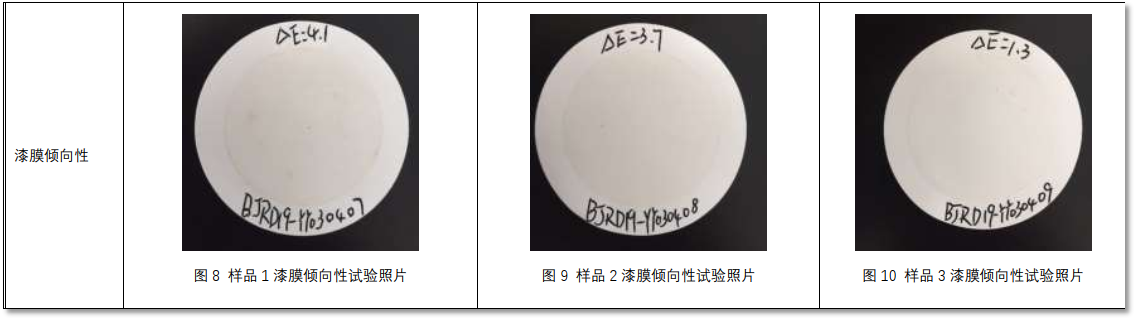

3.1.2 Popeza mafuta opaka mafuta asinthidwa kwa nthawi yosachepera chaka chimodzi, ubwino wa mafutawo wapambana mayeso musanayendetse.Pofuna kuthetsa kukayikira, kampaniyo idatumiza mafuta opaka ku kampani ya akatswiri kuti akayesedwe ndikuwunika.Kampani yaukadaulo imatsimikizira kuti chophatikizira pamwamba pake ndi varnish yoyambirira, MPC ( varnish propensity index ) (onani Chithunzi 4)

Chithunzi 4 Lipoti laukadaulo wowunikira mafuta loperekedwa ndiukadaulo wowunikira mafuta

3.1.3 Mafuta opaka mafuta omwe amagwiritsidwa ntchito mu chowonjezera ndi Shell Turbo No. 46 turbine mafuta (mafuta amchere).Pamene mafuta amchere ali pa kutentha kwakukulu, mafuta odzola amapangidwa ndi okosijeni, ndipo zinthu zowonongeka zimasonkhana pamwamba pa chitsamba chonyamula kuti apange varnish.Mafuta opaka m'mamineral amapangidwa makamaka ndi zinthu za hydrocarbon, zomwe zimakhala zokhazikika kutentha komanso kutentha pang'ono.Komabe, ngati mamolekyu ena (ngakhale ochepa kwambiri) a hydrocarbon akumana ndi ma oxidation pa kutentha kwambiri, mamolekyu ena a hydrocarbon nawonso amakumana ndi ma chain reaction, omwe ndi mawonekedwe a hydrocarbon chain reaction.

3.1.4 Akatswiri opanga zida adafufuza mozungulira thandizo la zida, kuzizira kwa mapaipi olowera ndi potuluka, kuzindikira kutayikira kwa dongosolo lamafuta, komanso kukhulupirika kwa kafukufuku wa kutentha.Ndipo m'malo seti ya mayendedwe kumapeto sanali pagalimoto wa otsika-anzanu mbali ya expander, koma pambuyo pa galimoto kwa mwezi umodzi, kutentha akadali anafika 110 ℃, ndiyeno panali kusinthasintha lalikulu kugwedera ndi kutentha.Zosintha zingapo zidapangidwa kuti zifikire kufupi ndi zomwe zidalipo kale, koma pafupifupi popanda zotsatira (onani Chithunzi 5).

Chithunzi 5 Trend tchati cha zizindikiro zogwirizana kuyambira February 13 mpaka March 29

wopanga MAN Turbo, pansi pa zomwe zikugwira ntchito powonjezerapo, ngati kuchuluka kwa mpweya kumakhala kokhazikika pa 120 t / h, mphamvu yotulutsa ndi 8000kw, yomwe ili pafupi ndi mphamvu yapachiyambi ya 7990kw pansi pazikhalidwe zogwirira ntchito;Pamene voliyumu ya mpweya ndi 1 30 t/h, mphamvu yotulutsa ndi 8680kw;ngati mpweya wolowa mpweya ndi 1 46 t/h, linanena bungwe mphamvu ndi 9660kw.Popeza kuti ntchito yochitidwa ndi mbali yochepetsetsa imakhala ndi magawo awiri mwa magawo atatu a zowonjezera, mbali yochepetsetsa ya expander ikhoza kukhala yodzaza.Pamene kutentha kumapitirira 110 ° C, kugwedezeka kwamtengo wapatali kumasintha kwambiri, kusonyeza kuti varnish yomwe yangopangidwa kumene pamwamba pa shaft ndi chitsamba choberekera imadulidwa panthawiyi (onani Chithunzi 6).

Chithunzi 6 Table balance balance of power unit of expansion unit

3.2Kusanthula Njira Zamavuto Amene Aripo

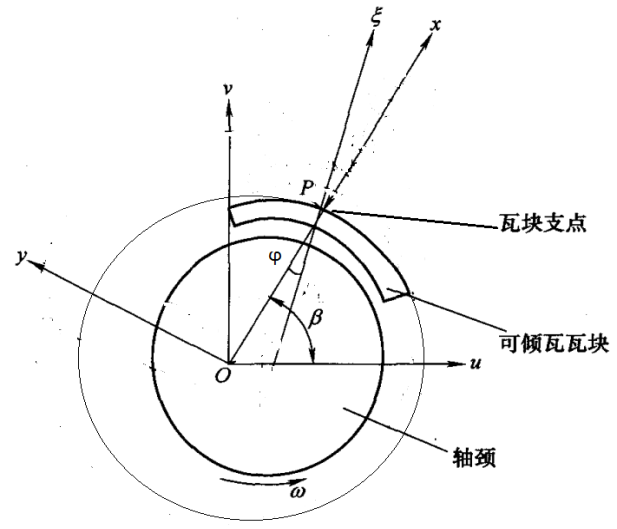

3.2.1 Monga momwe tawonetsera mu Chithunzi 7, zikhoza kuwoneka kuti mbali yomwe ikuphatikizidwa pakati pa kugwedezeka pang'ono kwa fulcrum ya tile block ndi yopingasa yogwirizanitsa mzere mu dongosolo logwirizanitsa ndi β , angle ya swing ya tile block ndi φ , ndi tilting pad wonyamula dongosolo wopangidwa ndi matailosi 5, pamene matailosi Pamene PAD ndi pansi mafuta filimu kuthamanga, popeza fulcrum wa pad si mtheradi olimba thupi, malo a fulcrum pad pambuyo psinjika mapindikidwe adzakhala. kutulutsa kusuntha pang'ono motsatira njira yojambulira ma geometric chifukwa cha kuuma kwa fulcrum, potero kumasintha chilolezo ndi makulidwe a filimu yamafuta [1.] .

Fig.7 Gwirizanitsani kachitidwe ka pedi imodzi yokhala ndi pad yopendekera

3.2.2 Zitha kuwoneka kuchokera ku Chithunzi 1 kuti rotor ndi ndondomeko ya mtengo wa cantilever, ndipo choyikapo ndicho chigawo chachikulu cha ntchito.Popeza mbali yoyendetsa ndi mbali yoyendetsa galimoto, pamene mpweya ukuwonjezeka kuti ugwire ntchito, tsinde lozungulira pa mbali ya chopondera liri mumkhalidwe wabwino mu chitsamba choberekera chifukwa cha zotsatira za mpweya wa mpweya, ndipo kusiyana kwa mafuta kumakhalabe kwachilendo.Munthawi ya ma meshing ndikutumiza torque pakati pa magiya akulu ndi ang'onoang'ono, ndi izi ngati fulcrum, kusuntha kwaulele kwa shaft yopanda mbali kumakhala kochepera pamikhalidwe yodzaza, ndipo kupanikizika kwake kwa filimu ndikokwera kuposa kwa ena. mayendedwe, kupanga malowa mafuta Kuuma kwa filimu kumawonjezeka, kuwonjezereka kwa filimu ya mafuta kumachepa, ndipo kutentha kwapakati kumawonjezeka, zomwe zimapangitsa varnish.

3.2.3 Vanishi mumafuta amapangidwa makamaka m'mitundu itatu: oxidation yamafuta, mafuta "micro-combustion", ndi kutulutsa kotentha kwambiri komweko.Varnish iyenera kuyambitsidwa ndi "micro-combustion" ya mafuta.Makinawa ndi awa: mpweya wina (nthawi zambiri zosakwana 8%) udzasungunuka mu mafuta opaka mafuta.Pamene malire a kusungunuka adutsa, mpweya wolowa mumafuta udzakhalapo mu mafuta ngati mawonekedwe a thovu loyimitsidwa.Pambuyo polowa mu bere, kuthamanga kwapamwamba kumapangitsa kuti ming'omayi ikhale yothamanga kwambiri, ndipo kutentha kwamadzimadzi kumakwera mofulumira kumayambitsa "micro-combustion" ya adiabatic ya mafuta, zomwe zimapangitsa kuti zikhale zochepa kwambiri zosasungunuka.Zosungunuka izi ndi polar ndipo zimakonda kumamatira kuzitsulo zachitsulo kupanga ma varnish.Kupanikizika kwakukulu, kumachepetsa kusungunuka kwa chinthu chosasungunuka, komanso kumakhala kosavuta kuti muchepetse ndikukhazikika kuti mupange varnish.

3.2.4 Ndi mapangidwe a varnish, makulidwe a filimu ya mafuta mu dziko lopanda ufulu amakhala ndi varnish, ndipo panthawi imodzimodziyo kuthamanga kwa filimu ya mafuta kumachepa, ndipo kutentha kumakwera pang'onopang'ono, komwe kumawonjezeka. kukangana kwapakati pa chitsamba chonyamula ndi tsinde, ndi vanishi woyikidwa kumapangitsa kuti kutentha kwapang'onopang'ono ndi kukwera kwa kutentha kwamafuta kumapangitsa kutentha kwa chitsamba.Pamapeto pake, magaziniyo imapaka vanishi, yomwe imawonetsedwa ndi kusinthasintha kwamphamvu kwa shaft vibration.

3.2.5 Ngakhale mtengo wa MPC wa mafuta owonjezera siwokwera, pamene pali varnish mu dongosolo la mafuta odzola, kusungunuka ndi mpweya wa tinthu ta varnish mu mafuta ndi ochepa chifukwa cha mphamvu zochepa za mafuta opaka mafuta kuti asungunuke. mitundu ya varnish.Ndi dynamic balance system.Ikafika pamalo odzaza, ma varnish amapachikidwa pa bere kapena pad, zomwe zimapangitsa kusinthasintha kwa kutentha kwa bearing pad, yomwe ndi ngozi yayikulu yobisika yomwe imakhudza ntchito yotetezeka.Koma chifukwa amamatira pa bearing pad, ndi chimodzi mwa zifukwa zomwe zimachititsa kuti kutentha kwa pad kubera.

4 Miyezo ndi Zotsutsana nazo

Kuchotsa kudzikundikira kwa varnish pa chotengera kungathe kuonetsetsa kuti kunyamula kwa unit kumayendera kutentha kolamulidwa.Kupyolera mu kafukufuku ndi kulankhulana ndi ambiri opanga varnish kuchotsa zipangizo, tinasankha Kunshan Winsonda, amene ali ndi zotsatira zabwino ntchito ndi mbiri msika, kupanga WVD-II electrostatic adsorption + utomoni adsorption, amene ndi pawiri varnish kuchotsa zipangizo kuchotsa utoto.membrane.

Oyeretsa mafuta a WVD-II amaphatikiza bwino ukadaulo woyeretsera ma electrostatic adsorption ndi ukadaulo wosinthira ion, kuthetsa varnish yosungunuka kudzera pa resin adsorption, ndikuthana ndi vanishi wocheperako kudzera pa electrostatic adsorption.Tekinoloje iyi imatha kuchepetsa zomwe zili mumatope munthawi yochepa , M'kanthawi kochepa kwa masiku angapo, makina opangira mafuta oyambira omwe ali ndi matope ambiri / varnish amatha kubwezeretsedwanso kumayendedwe abwino kwambiri, komanso vuto la kukwera pang'onopang'ono. Kutentha kwa mpweya wopangidwa ndi varnish kumatha kuthetsedwa.Ikhoza kuchotsa bwino ndikuletsa matope osungunuka ndi osasungunuka omwe amapangidwa panthawi ya ntchito yabwino ya turbine ya nthunzi.

Mfundo zake zazikulu ndi izi:

4.1 Ion kusinthana utomoni kuchotsa varnish kusungunuka

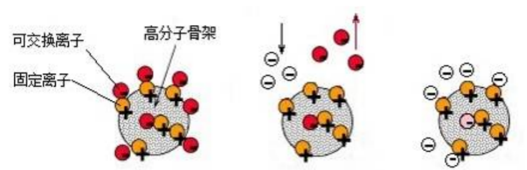

Utoto wosinthira ion umapangidwa makamaka ndi magawo awiri: mafupa a polima ndi gulu la ion exchange.Mfundo ya adsorption ikuwonetsedwa mu Chithunzi 8,

Chithunzi 8 Mfundo ya ion-interaction resin adsorption

Gulu losinthira limagawidwa kukhala gawo lokhazikika komanso gawo losunthika.Gawo lokhazikika limamangidwa pa matrix a polima ndipo silingathe kusuntha momasuka, ndipo limakhala ion yokhazikika;gawo losunthika ndi gawo lokhazikika zimaphatikizidwa ndi zomangira za ayoni kuti zikhale ion yosinthika.Ma ions okhazikika ndi ma ion a mafoni ali ndi ndalama zotsutsana motsatana.Pa chitsamba chonyamula, gawo la m'manja limawonongeka kukhala ma ions osuntha mwaufulu, omwe amasinthanitsa ndi zinthu zina zowonongeka ndi malipiro omwewo, kotero kuti amaphatikizana ndi ma ion okhazikika ndipo amatsatiridwa mwamphamvu pazitsulo zosinthanitsa.Pagulu, amachotsedwa ndi mafuta, osungunuka varnish ochotsedwa ndi ion exchange resin adsorption.

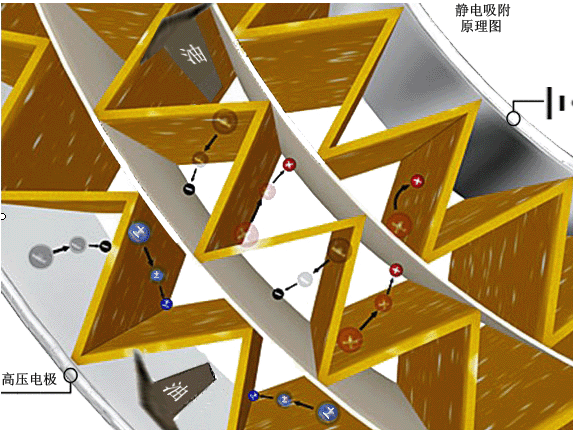

4.2 Ukadaulo wotsatsa wa Electrostatic kuchotsa varnish yoyimitsidwa

Electrostatic adsorption luso makamaka amagwiritsa jenereta mkulu-voltage kupanga mkulu-voteji electrostatic kumunda polarize particles anaipitsa mu mafuta kusonyeza mlandu zabwino ndi zoipa motero.Tinthu tandale tikulumikizana ndikusunthidwa ndi tinthu tambiriyi, ndipo pamapeto pake timakhala tinthu tating'onoting'ono ndi ophatikizidwa ndi osonkhanira (onani Chithunzi 9).

Chithunzi 8 Mfundo yaukadaulo wa electrostatic adsorption

Ukadaulo woyeretsera mafuta wa Electrostatic utha kuchotsa zowononga zonse zosasungunuka, kuphatikiza zonyansa za tinthu tating'onoting'ono ndi vanishi woyimitsidwa wopangidwa ndi kuwonongeka kwamafuta.Komabe, zosefera zachikhalidwe zimatha kungochotsa tinthu tating'onoting'ono tomwe timafanana, ndipo ndizovuta kuchotsa submicron. mulingo woimitsidwa varnish .

Dongosololi limatha kuthetseratu varnish yomwe idayikidwa ndikuyika pachovala, potero kuthetseratu chikoka cha kutentha kwa pad ndi kusintha kwa kugwedezeka komwe kumachitika chifukwa cha varnish, kotero kuti unit imatha kuthamanga mokhazikika kwa nthawi yayitali .

5 Mapeto

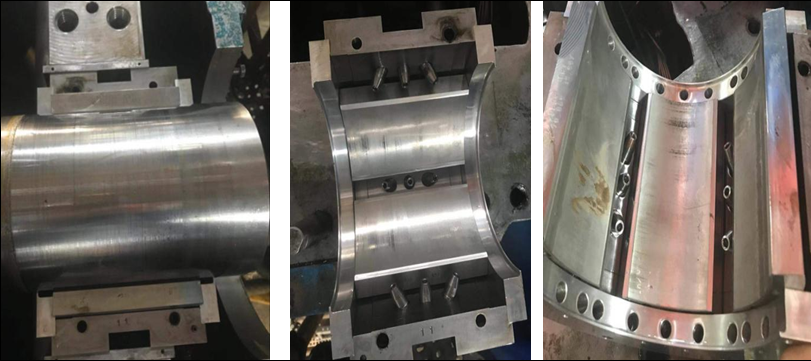

WSD WVD-II vanishi yochotsa unit idagwiritsidwa ntchito, pazaka ziwiri zowonera, kutentha kwanthawi zonse kumasungidwa pafupifupi 90 ° C, ndipo chipangizocho chakhala chikugwira ntchito bwino.Filimu ya varnish inapezedwa (onani Chithunzi 10).

Chithunzi chakuthupi chokhala ndi disassembly mutakhazikitsa kuchotsa varnish

zida

maumboni:

[1] Liu Siyong, Xiao Zhonghui, Yan Zhiyong, ndi Chen Zhujie.Kayeseleledwe ka manambala ndi kafukufuku woyesera pamayendedwe osinthika a pivot zotanuka ndi zotayira zopendekera zoyenda pad [J].Chinese Journal of Mechanical Engineering, October 2014, 50(19):88.

Nthawi yotumiza: Dec-13-2022